Geometrical Tolerances

Geometrical

tolerances control the geometry in drawing. Perfect geometry or close

geometrical relations improve functionality.

There

are following geometrical tolerances which are classified according to their

use in different situations.

To control the form of geometry

1-Straightness 2-Flatness 3-Cylinder

city 4-Circularity

To control orientation of

geometry

5-Parallelism 6-Perpendicularity 7-Angularity

To control the profile of

geometry

8-Profile

of a surface 9-Profile of a line

To control the run out

10-Circular

run out 11-Total Run out

To control the location of

geometry

12-Position 13-Concentricity 14-Symmetry

Let

us now see definition, where to use and how to assign each type.

Form controlling geometric

tolerances‘

These tolerances ask us to maintain the

outline of a profile. They have no

relation with any center or any datum.

They are defined by them selves only.

1-Straightness

Definition

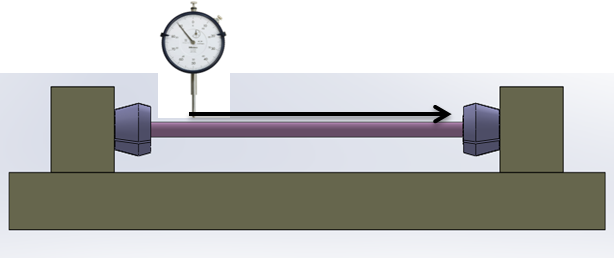

In the image shown here the straightness

error is of 0.05 mm.

A kind of bent profile is not acceptable

if a diff. in between

two extreme bend points is 0.05 mm.

How to measure it.

How to show this in drawing

This is a mold tool ejector pin and it's

straight ness along the diameter

2.00 mm

Is needed in between 0 to 0.02. plus or minus.

1-A fixture manufactured with a very high

precision will give exact straightness value. Ensure that pin does not swivel

during testing.

2-Start the dial indicator from one side

and move it towards other end slowly.

Note the deviation of indicator.

Calculate the diff between min. and max. values.

3-A fixture will give wrong result if it

is manufactured at precision

less than 0.02 mm

2-Flatness

Definition

It defines the straightness of flat

surface.

In the first image, the surface area

covered by length and width of

rectangular top surface is having bend,

twist or irregularity of 0.05 mm.

How to show this in drawing

These are shown in a box and leader

placed on the face where

flatness in critical to quality.

How to measure it

Place

the plate on surface plate. Move dial probe on whole surface area. Note the

highest and lowest reading.

Another

method is applying a blue paste on one of the plates, mate them as to be mated

in real time, if all the blue gets transferred on second plate, then plates are

flat enough. How ever this method will

give

result as “Yes” or “No” only.

Straightness

is applicable to straight profile and flatness is applicable to planar surface.

Both

the terms govern the bent or twisting occurring during normal

usage.

Is Straightness/Flatness related to s/f

finish?

No a

s/f with bad finish will have irregularity as shown in last image.

So

separate instruction shall be given to sensitise the manufacturer

about

surface finish.